- Rodovia Raposo Tavares, km 381

- tnl@tecnal.ind.br

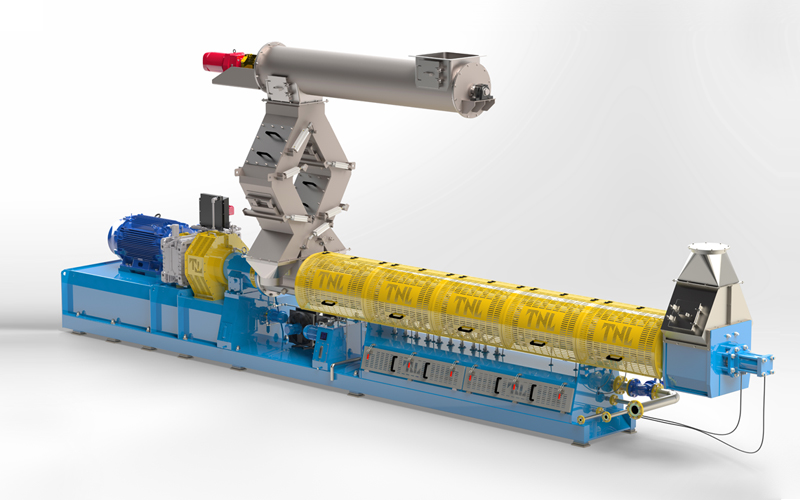

EXPANDERS

For soybeans, sunflower seeds, rapeseed, corn, cottonseed, rice bran, etc.

Capacities: from 200 tpd to 4,000 tpd.

TNL Tecnal was the first company in the world to design and manufacture, in 1978, expanders for application in seed preparation for oil extraction. Since then, TNL Tecnal has been continuously innovating and updating its Expanders.

Years of experience have led TNL Tecnal to have the most reliable and efficient expanders in the world, with more than 500 expanders running successfully in more than 200 customers around the world.

TNL Tecnal Expanders provide maximum efficiency and minimum wearing, thus low maintenance cost.

TNL Tecnal expanders will bring great benefits to you:

Main Features:

Drainage Cage

TNL Tecnal expanders can be equipped with drainage cage for high oil content seeds (so, expeller presses are eliminated). About 1/3 of the oil can be removed in the drainage cage.