- Rodovia Raposo Tavares, km 381

- tnl@tecnal.ind.br

AUTOMATION

Automation for animal feed plants means food safety, quality, efficiency, optimization of processes and resources, real-time management, among many other benefits. TNL Tecnal prepares your plant to produce more, spending less.

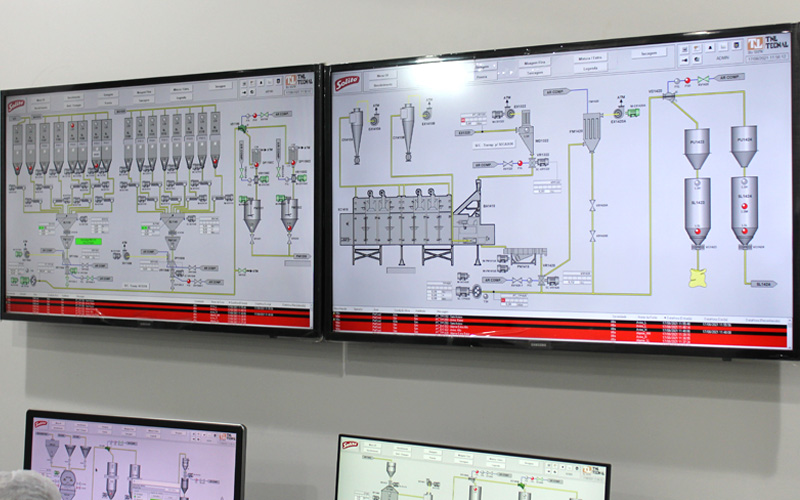

The entire plant can be controlled via PLC (Programmable Logic Controller). The automation system is operationalized through an interface called supervisory system, where each stage of the process has its own viewing and control screen. This interface integrates man and machine in a friendly way, allowing visualization and control of the entire production process, with real-time monitoring and data analysis.

Access to the equipment commands that make up each stage of the process is carried out on the computer screen and interacts with processing times and temperatures, machine alarms, hours worked, raw material inputs and consumption (with traceability), among others.

It is a vast universe of possibilities that result in greater efficiency, increased productivity, better quality and rational use of resources. The system generates analytical reports that contribute to optimizing the production process and decision-making, in the search for excellence.