EXTRUSORA - EDR

Dupla Rosca.

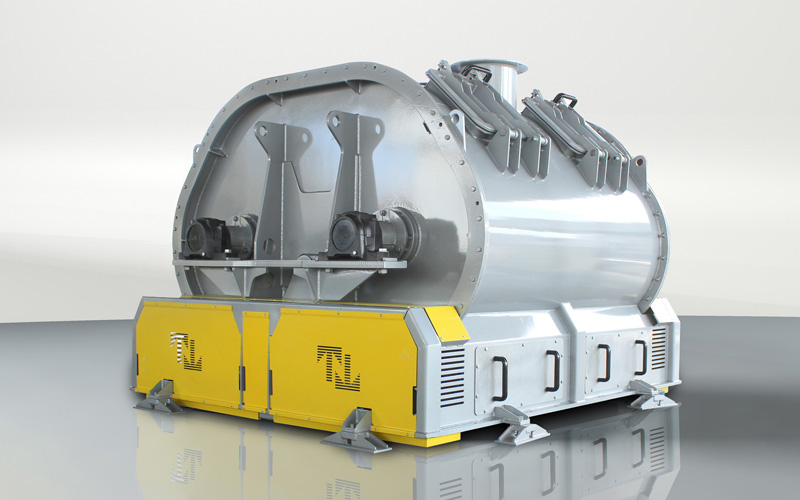

Misturador MDP – Recobrimento à Vácuo

Utilização: Farelo, Ração Extrusada, Ração Peletizada.

Capacidade: 3-15 ton/h

O Misturador MDP TNL TECNAL possui sistema por Batch com duplo eixo de pás, conta com dosagem precisa que por meio de um pulmão apoiado em células de carga, que faz a pesagem do produto, também tanque de gordura, palatabilizantes líquidos e pó apoiados em células de carga, que serão adicionados.

Destaques do Produto

Vantagens do Produto