- Rodovia Raposo Tavares, km 381

- tnl@tecnal.ind.br

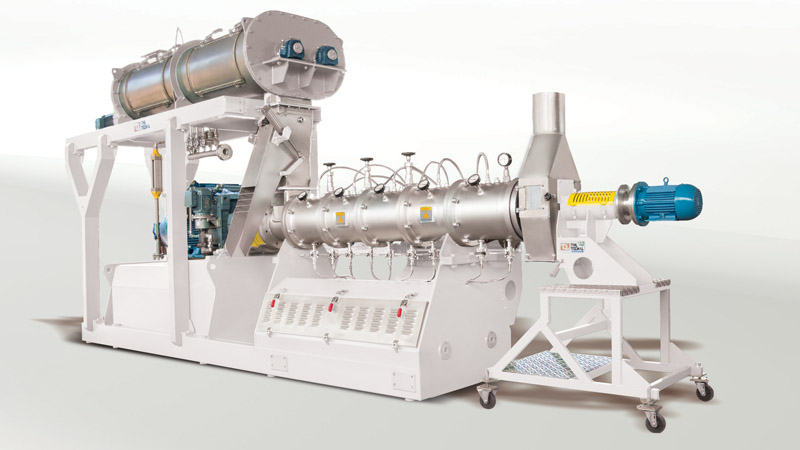

Extrusora EAP

Utilização: farinhas para extrusão.

Capacidade: 5-15 ton/h

As Extrusoras EAP TNL TECNAL foram desenvolvidas para produzir kibbles de melhor aparência e maior homogeneidade, qualificando o aspecto do alimento para o animal.

Corpo com módulos em aço carbono (1 módulo de entrada, 4 módulos intermediários e um módulo de saída), helicoides fundidos (em configurações e aços diferentes), camisas estriadas fundidas. Todos com a opção em aço inoxidável;

Mancalização anterior e posterior, proporcionando maior estabilidade do eixo.

Novo sistema MAP (Matriz de Alta Performance) - matrizes com cortador motorizado acoplado por meio de cardam. Traz agilidade no setup da troca de produtos, melhor acabamento no kibble. Não é apenas um anel perfurado, mas um dispositivo para homogeneização da massa controlando a expansão de acordo com cada produto, antes da formação e corte.

Aumento de produtividade e na qualidade da formação do kibble produzindo cortes perfeitos, eliminando rebarbas e consequentemente diminuindo consideravelmente a formação de finos.

Destaques do Produto

Vantagens do Produto